Note: this guide is for an open space water tank ( no support columns)

Please thoroughly read through this installation guide before starting.

Also you must make sure your water tank is structurally sound before a liner can be installed.

Your new tank liner can be fitted into corrugated, poly, flat steel and concrete tanks that have either open or closed tops. The type of tank you have will determine how the tank liner is to be installed.

Before You Start

We recommend that you have the following:

- Wet / dry vacuum or dust pan & brush

- Heavy-duty PVC tape

- Chalk stick for marking out

- Screwdriver / stillson for removing outlet fittings

- Sand, newspaper or geotextile underlay

- Drill (preferably cordless) with 5mm bit

- Ladder

- Stanley knife

- Rubber mallet

- 1 cartridge of silicone natural cure sealant per 6m of tank perimeter when using extrusion

- File and Hacksaw (for removing sharp edges and old fittings)

OPTIONAL ITEMS

- 5mm pop rivets & rivet gun (or suitable fasteners, depending on type of tank)

- Faceplate to seal around existing outlets

- Fixing extrusion (or other fastening method)

- Old garden hose & wire (optional for securing corrugated tanks)

IMPORTANT

Don’t let hot drill bits or other sharp tools come into contact with the liner!

Water Tank Preparation

Prior to placing, unfolding and installing the tank liner ensure that:

- the tank structure is completely dry and clean of all rust and scale.

- any metal surfaces should be coated with suitable rust proofing agent(s) and cured thoroughly.

- the tank is completely drained.

- make sure there are no hazards such as sharp edges, protrusions, stones, roots etc that have the potential to damage or puncture the tank liner.

- do not wear shoes or any other foorwear that could damage the liner.

- ensure any tools or ladders are placed on protective fabric or have protective feet/boots attached.

- drill new overflow outlet into tank wall if needed, refer to overflow pipe installation guide.

Installing the DURATANK Tank Liner Underday

If you are using a geotextile protection underlay (highly recommended) it will be supplied in two pieces, a base and a wall section. The base is simply placed on the floor as evenly as possible. The wall underlay will then be temporarily hung in place until the tank liner is installed.

Hang the geotextile protection underlay along the wall in four different places (best to use non-permanent fixing, such as heavy duty tape); this can be done by using the 3, 6, 9 and 12 o’clock positions or in the 4 corners for square or rectangular tanks.

For open top tanks, hang the liner over the edge. It is often a good idea to drill all of the fixings positions prior to hanging the liner. (Ensure all drill swarfetc is removed before hanging geotextile and liner). Do not worry about the rest of the geotextile wall as this can be hung at the same time as hanging the liner wall. If you do pre-drill all of the fixing locations for hanging the liner, make sure that there is a gap of at least 200mm between each fixing location.

The wall underlay will also overlap the base underlay by a small amount. You can tape any excess floor geotextile to the wall and overlap any excess material from the wall and or floor.

Put pressure on the geotextile adjacent to any hazards to make sure none of the hazards penetrate the geotextile. If the hazard pierces or is likely to pierce the geotextile, remove the puncture point.

Securing The New Liner

There are two ways to secure the tank liner installation, depending on the type of tank you have. With open top tanks, the liner is folded over the edge by about 150 mm and secured around the outside with wire (in the case of corrugated tanks).

There are two ways to secure the tank liner installation, depending on the type of tank you have. With open top tanks, the liner is folded over the edge by about 150 mm and secured around the outside with wire (in the case of corrugated tanks).

Carefully unroll the liner on the tank floor and open the liner up, making sure that the centre of the liner (marked with 300mm diameter circle) is exactly in the centre of the tank. Take care when unfolding the liner and ensure that you unfold each fold one at a time. Make sure that the wall to base seam (the welded seam that continuously goes all the way around the tank) is pushed up against the floor/wall juncture (where wall meets the floor of the tank).

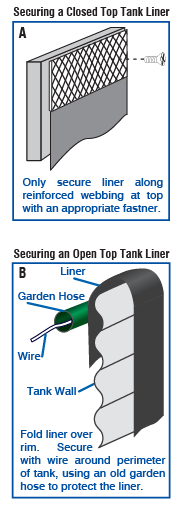

SECURING A LINER IN A CLOSED TOP TANK – Diagram A

With closed top water tanks, the liner can be secured with rivets, self- tapping screws or concrete wall anchors, depending on the type of tank. Mount or screw through the webbing.

Start hanging the liner wall by using the same method as you used when hanging the geotextile on the wall the 12, 3, 6 and 9 o’clock positions or the four corners. Ensure that the wall section is hung vertically. Check to see that the pleats (folds) are hanging vertically. When you start to hang the rest of the wall, hold the geotextile underlay wall material behind the liner wall and attach both of them at the same time.

If the folds (pleats) on the tank liner wall are not vertical then the tank liner will have to be re-adjusted.

At NO POINT is the liner to be under any tension in any place. The liner is made oversize and should not be tight, taunt or under load at any point.

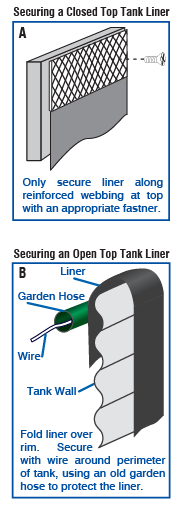

SECURING A LINER IN AN OPEN TOP TANK – Diagram B

Check both the inside of the tank as well as the rim of the outside of the tank for any sharp or protruding objects that can either damage or puncture your liner. The Geotextile protection underlay should help protect the liner as much as possible when it is dropped over the top of the tank.

Once the liner is inside the tank, unroll the liner and make sure the liner is in place by checking the perimeter wall to base seam is right in the wall to base join of the tank. Fold both your Geotextile protection underlay wall and your liner over the top of the tank, making sure that any wrinkles which appear on the liner wall during installation are eliminated (pull the liner wall against the wrinkles).

Once there are no more wrinkles on the liner wall, fix the liner to the outer rim of the tank by tying fencing wire around the perimeter of the tank. Make sure that there is plenty of slack at the bottom of the liner wall inside the tank so that it is easier to install your tank fittings.

Please Note: Due to potential risk of the fencing wire damaging the liner, it is strongly recommended that the wire is covered (example: Garden Hose).

Re-adjusting The New Tank Liner

The easiest way to do this is to leave excess material between the four initial hanging points and then keep attaching in the middle (between 2 points). Once the 12, 3, 6, 9 o’clock or corner positions have been attached, go to the mid points between each of the above initial attaching points. Continue attaching mid points until the liner has been completely attached in each section.

Once the liner wall has been fully hung (attached) all the way around the tank and the folds/pleats are all about the same size and spacing all around the perimeter, walk around the base floor junction and start pushing the wall to base seam (the same as talked about in step 2) into where the floor of the tank meets the wall. If done correctly then there should be some overhang were the liner wall folds over itself near the base, the reason for this is so that when filling the tank there is no stress on the wall.

Installing the Fittings for Poly and Metal Tanks

When installing a fitting, ensure that there is sufficient slack material all around the penetration. There should be no stretching of material near or at the fitting. Locate where your fitting needs to be positioned and cut a hole smaller than the threaded pipe for you fitting into the tank liner.

When installing a fitting, ensure that there is sufficient slack material all around the penetration. There should be no stretching of material near or at the fitting. Locate where your fitting needs to be positioned and cut a hole smaller than the threaded pipe for you fitting into the tank liner.

Once this has been done, put a bead of potable grade silicon around the threaded pipe of the fitting (just above the rubber gasket) and push the fitting through the hole of the liner, making sure the fitting goes through the tank penetration to the other side of the tank.

After the fitting has been installed from the internal side of the tank to the external side, tighten the second nut of the fitting against the outside of the tank, making sure that the fitting is as tight as possible.

Go back inside the tank and put a big bead of silicon all the way around the outside of the circumference of the fitting, as this will create an extra layer of waterproofing. Once this has been done, let the silicon dry and start checking the liner.

After Installation of Your New Tank Liner

The final step is to check the liner. In order to do this you will need to partially fill the tank (around 300mm to 400mm). If for any reason the tank cannot be filled or at least have 300 – 400mm of water covering the floor, you must secure the liner in such a way as to prevent any movement of the liner within the tank. When filling, if there is any stress or tension on the liner, drain the tank and re-adjust the liner to eliminate the problem.

-27.736200

153.223745

A water tank liner is a great way to extend the life of a water tank that is still structurally sound but leaks water. Tank liners also have the added benefit in that further leaks are usually prevented as there is now a permanent membrane between the water any potential spot where a leak may form due to rust, cracking or ground movement.

A water tank liner is a great way to extend the life of a water tank that is still structurally sound but leaks water. Tank liners also have the added benefit in that further leaks are usually prevented as there is now a permanent membrane between the water any potential spot where a leak may form due to rust, cracking or ground movement.

Place a suitably sized piece of cardboard around the skimmer box and secure with masking tape. Place the hose of the vacuum cleaner (a Wet & Dry type is recommended) through the pool water return fitting in the wall of the pool until it is around 250mm to 300mm above the sand. Tape around the hose at the wall making a seal (Diagram C). Double check that the liner has no large wrinkles or surplus material and make sure it is secured by the plastic strips.

Place a suitably sized piece of cardboard around the skimmer box and secure with masking tape. Place the hose of the vacuum cleaner (a Wet & Dry type is recommended) through the pool water return fitting in the wall of the pool until it is around 250mm to 300mm above the sand. Tape around the hose at the wall making a seal (Diagram C). Double check that the liner has no large wrinkles or surplus material and make sure it is secured by the plastic strips.

When installing a fitting, ensure that there is sufficient slack material all around the penetration. There should be no stretching of material near or at the fitting. Locate where your fitting needs to be positioned and cut a hole smaller than the threaded pipe for you fitting into the tank liner.

When installing a fitting, ensure that there is sufficient slack material all around the penetration. There should be no stretching of material near or at the fitting. Locate where your fitting needs to be positioned and cut a hole smaller than the threaded pipe for you fitting into the tank liner. When renovating a pool or even installing a liner into a new pool, you need to consider the type of liner for the pool you are using. This question is also more than just “is it above ground or and inground pool” question. Most people are aware that PVC

When renovating a pool or even installing a liner into a new pool, you need to consider the type of liner for the pool you are using. This question is also more than just “is it above ground or and inground pool” question. Most people are aware that PVC

There are many ways you can make a water tank, all depending on your usage, location and budget. In most cases when a water tank fails, there are several options for the

There are many ways you can make a water tank, all depending on your usage, location and budget. In most cases when a water tank fails, there are several options for the